Activation method and protection principle of BMS

Equalization principle of lithium battery protection board, activation method of lithium battery protection board. As we all know, lithium battery is a new energy battery that will be used in various fields at present. However, many people do not know that lithium battery needs the protection of a protective plate. The protective plate plays a crucial role in the use of batteries. Now let's learn about the activation method and protection principle of the protective plate.

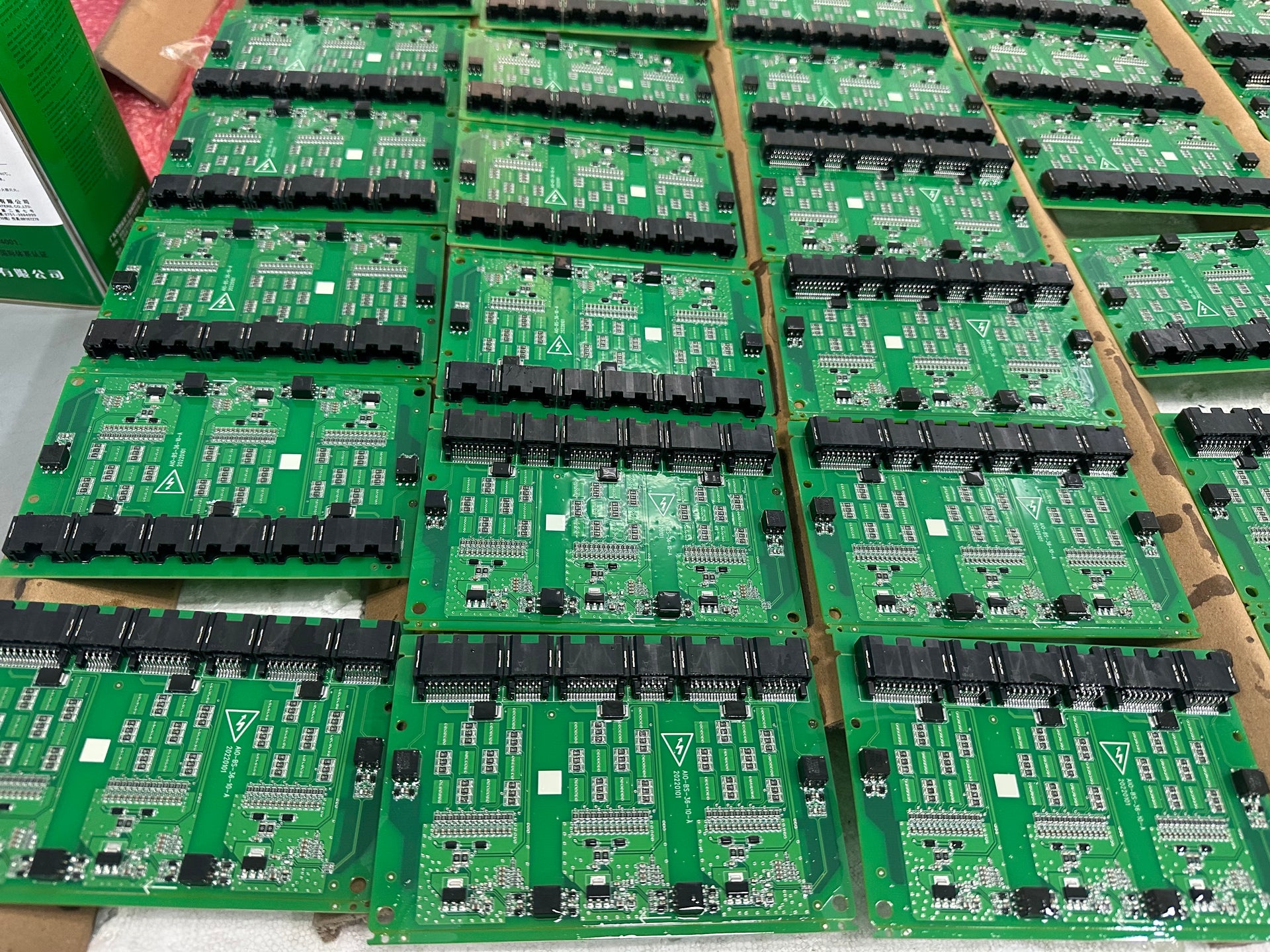

Lithium battery protection plate

The lithium battery protection board is used for charging and discharging protection of series lithium battery packs; When fully charged, it can ensure that the voltage difference between each single battery is less than the set value (generally ± 20mV), realize the uniform charging of each single battery of the battery pack, and effectively improve the charging effect under the series charging mode; At the same time, detect the overvoltage, Undervoltage, overcurrent, short circuit and over temperature status of each single battery in the battery pack to protect and extend the service life of the battery; The undervoltage protection prevents each single battery from being damaged due to over-discharge during discharge.

The finished lithium battery mainly consists of two parts: a lithium battery cell and a protective plate. The lithium battery cell mainly consists of a positive plate, diaphragm, negative plate, and electrolyte; The positive plates, diaphragms and negative plates are wound or laminated, packed, filled with electrolyte, and then sealed to make the electric core.

Equalization principle of lithium battery protection plate

The commonly used equalizing charging technologies of lithium battery protection board include constant shunt resistance equalizing charging, on/off shunt resistance equalizing charging, average battery voltage equalizing charging, switching capacitor equalizing charging, step-down converter equalizing charging, inductance equalizing charging, etc.

When charging a group of lithium batteries in series, ensure that each battery is charged evenly, otherwise, the performance and life of the whole group of batteries will be affected during use. However, the existing single lithium battery protection chip does not include the equalizing charge control function, and the equalizing charge control function of multiple lithium battery protection chips requires an external CPU; Through the serial communication with the protection chip (such as I2C bus), the complexity and design difficulty of the protection circuit are increased, the efficiency and reliability of the system are reduced, and the power consumption is increased.

The charging overvoltage protection control signal of a single lithium battery protection chip in the control circuit of the lithium battery pack protection board system is isolated by optocoupler and output in parallel, providing grid voltage for the conduction of the charging switch devices in the main circuit; If one or more lithium batteries enter the overvoltage protection state during the charging process, the overvoltage protection signal will control the discharge of the shunt discharge branches connected in parallel at the positive and negative poles of the single lithium battery, and the corresponding single lithium battery connected in series in the charging circuit will be disconnected from the charging circuit.

Activation method of lithium battery protection board

The protection function of lithium batteries is usually completed by the protection circuit board and current devices such as PTC. The protection board is composed of electronic circuits. Under the environment of - 40 ℃ to+85 ℃, the voltage of the cell and the current of the charge-discharge circuit are monitored accurately at all times, and the current circuit is controlled on and off in a timely manner; PTC can prevent the battery from bad damage under high temperature.

Not all lithium battery protection boards need to be activated now, but some protection ICs need to be activated, and this is the old IC scheme. The old IC scheme requires this to make the protection board not work, so as to reduce the electrostatic discharge energy so that the lithium battery can be stored for a longer time. This is why the design requires charging activation.

If the lithium battery protection board needs to be activated after charging or completely disconnecting the load due to the current limiting protection, it is relatively troublesome. However, you can also short-connect B - (battery negative) and P - (discharge negative), and the protection will be released. Remember not to carry a heavy load (such as turning the bar all the time) when the short circuit is touched, or you may get a big spark, The root cause is that a large voltage difference is formed at both ends of the discharged MOS after protection. The short circuit is to directly reset the D-S level of the discharged MOS to 0V. At this moment, the protection is released.

How to activate the lithium battery protection board?

If the protection board needs to be activated after charging or completely disconnecting the load due to the current limiting protection, it is relatively troublesome. However, you can also short-connect B - (battery negative) and P - (discharge negative), and the protection will be released. Remember not to carry a heavy load when the short circuit is touched (such as turning the bar all the time), otherwise, there may be a lot of sparks, The root cause is that a large voltage difference is formed at both ends of the discharged MOS after protection. The short circuit is to directly reset the D-S level of the discharged MOS to 0V. At this moment, the protection is released.

The above is the equalization principle of the lithium battery protection board and the activation method of the lithium battery protection board. Do you understand? The normal working process of a lithium battery protection board is: when the cell voltage is between 2.5V and 4.3V, the first and third pins of DW01 output a high level (equal to the power supply voltage).